The shipbuilding industry is responsible for constructing ships and other floating vessels, typically in a shipyard. Numerous metals can be used for shipbuilding.

When choosing the best metals for ships, it is crucial to consider the metal’s yield strength and tensile strength. Steel and aluminium alloy are the most prevalent metals that meet these standards. However, aluminium boat extrusion is highly preferred over steel in the shipbuilding industry.

History of Aluminium Boat Extrusion

Aluminium extrusions are made by compressing the metal under high pressure unless it adopts a specific shape. Its vast history is briefly explained below:

· In the 1830s, a hull was riveted using 6061-T6 aluminium alloy;

· Since 1891, aluminium alloy has been utilized on ships. After over a century of research and development, they have become a viable material for the shipbuilding industry and are increasingly used in ship construction;

· In the 1940s, aluminium-magnesium alloys that were weldable and resistant to corrosion were produced;

· Aluminium welding technology emerged in the 1950s and 1960s, and the United States created 5086 and 5456 alloy aluminium plates and profiles;

· After the 1960s, the Aluminium alloy is becoming increasingly popular for its high tensile strength, low density, non-magnetic, high thermal conductivity, and electrical conductivity.

It is now widely employed in medium and small-sized passenger ships, speedboats, yachts, high-speed, patrol boats, missile boats, destroyers, and other applications.

Why Is Aluminium Better Than Steel?

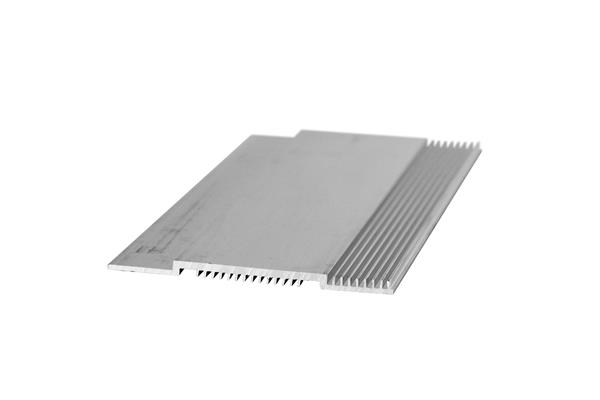

The reason behind aluminium extrusion profiles is that aluminium alloys offer many advantages over their steel equivalents. Not only because a ship constructed of aluminium alloys rather than steel weighs 60% lighter on average, but aluminium also resists corrosion and is a low-cost material to maintain. Accordingly, the market size of aluminium extrusion is expected to continue growing.

Major Advantages of Aluminium Boat Extrusion

Aluminium stands out among other materials and metals for its natural rust and corrosion resistance. This is why aluminium boat extrusion and fabrication are frequently seen in a wide range of marine applications. Below are some major advantages of aluminium boat extrusion:

· Longevity

In general, custom aluminium extrusions outlast products made of steel, plastic, or other metals, mostly because aluminium is exceedingly robust, especially for its weight and corrosion-resistant.

· Adaptability

Aluminium extrusions can also adapt to both cold and hot temperatures, making them useful in almost any climate. Those who trust aluminium extrusions are never disappointed with the result since it is a metal that always delivers you your money’s worth.

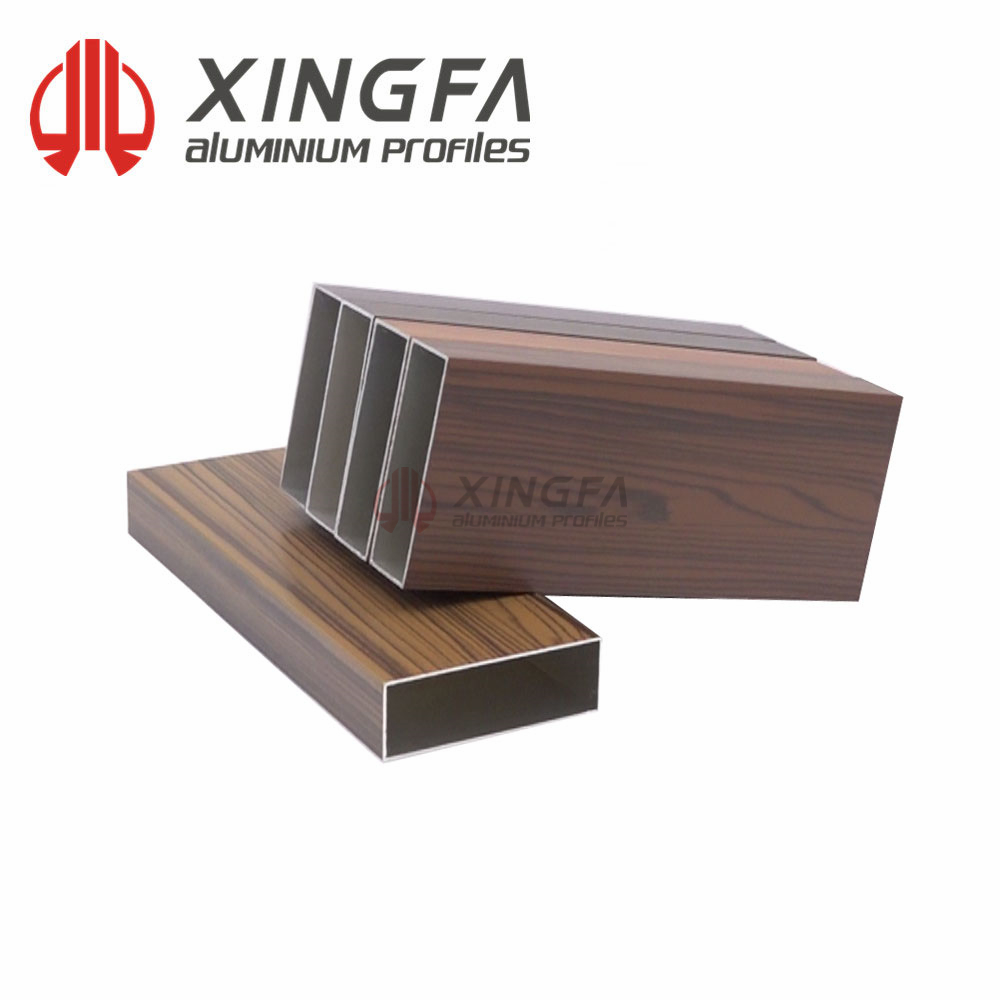

· Customizability

A tool steel mould is used in the aluminium extrusion phase to determine the shape and size of the final product. The steel mould molds the heated aluminium into the required shape. However, the alternatives are numerous when it comes to the size and shape of the mold extrusion to get the desired results.

· Economically and Environmentally Friendly

People who don’t like to splurge on building materials could contact an aluminium profile supplier, as aluminium is relatively economical, especially when considering its properties.

Being the most occurring metal on the planet, aluminium is an extremely cost-effective choice. Aluminium is also easily recycled, making it a more environmentally friendly metal than many others.

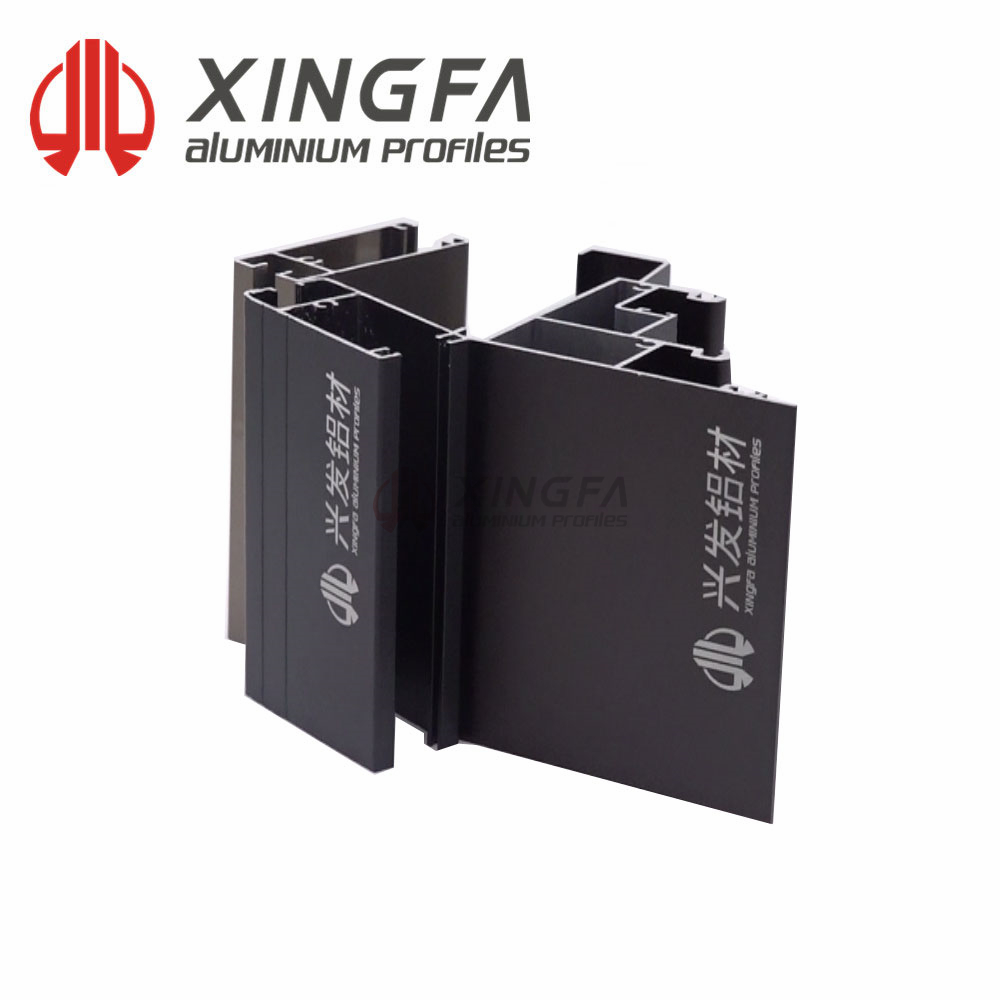

The Best Aluminium Supplier: Xingfa

If you’re seeking the best aluminium supplier, we’ll recommend Xingfa to you without any second thought. Xingfa, being the best quality aluminium profile manufacturer in China, was founded in 1984. Our company is specialized in producing aluminium windows, doors, curtain walls, and industrial aluminium profiles. Some of our distinctive highlights include, but are not limited to:

· Outstanding quality with certifications;

· Products with advanced technology;

· R&D capability.

If you want to find out how aluminium may help you streamline your manufacturing process while reducing the overall cost, get help from Xingfa.

In Conclusion

The marine sector has used aluminium alloys for almost a century and found them to be a sturdy, versatile, and, most importantly, corrosion-resistant alternative for your aluminium boat extrusion needs.

Xingfa is one of the best aluminium profile manufacturers in China; we have created more than 200,000 distinct types of aluminium extrusion profile specs and models and take pleasure in being a professional resource partner to our suppliers and customers.

Connect with us today to level up aluminium boat extrusion!