In 1860s, the birth of steam engine, the utilization of coal leads to a rapid increase of labour power, the beginning of industrial and economic revolution. Until 1970s, the appearance of Internal Combustion Engine, car industry, development of aviation industry, the world economic structure had changed from light to heavy industry. Nowadays, by the development of electric technology, hydroelectric, biochemical, wind, geothermal, ocean and other clean energy, human being have entered a green energy period.

As energy saving and recycling is becoming a hot debate among publicity, urgency of energy concerns, environmental issues coming from cars are being recognized as well. Reducing the car consumption of fuel energy, lower the emission of pollutants has became a priority problem of sustainable development of car industry.

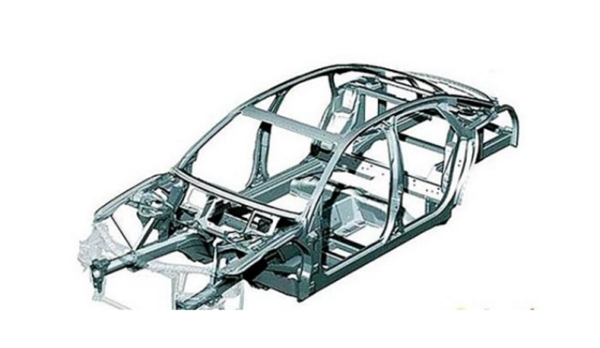

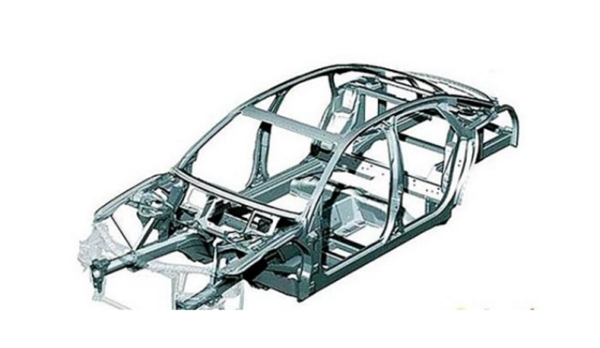

Speaking of cars, body light-weighting is not just simply reduce the weight, but also, in the context of ensuring hardness and security, applying rational designs and utilizing new material to reduce the weight. Car light-weighting is the main measure of reducing emission.

Aluminium profile has the advantages of low density, corrosion-resistance, compatible with casting, forging, stamping process. Indian first applying aluminium extrusion profiles on cars. According to records, Indian first using aluminium profile for crankcase in 1896. In early 20 century, aluminium made car body appeared and played a essential role in luxury and racing cars. In 1990, Japanese car giants used plenty of aluminum extrusion profiles on car manufactures and produced full-aluminum body sport car NSX. Beside that, aluminum has a recyclable rate up to 90%. Aluminum is becoming a necessary material in terms of cost, quality and application.

Car used aluminium alloy is divided into casting and deforming alloy.

Casting aluminium alloy is used for different types of cylinders, engine, clutch, pumps, gearbox, and other non-engine components such as brake disc. Deforming alloy includes different plate profiles, aluminium extrusion profiles and forging profiles. Aluminium extrusion profiles are widely used in every components in cars due to light, good hardness, process and welding performances. It is widely applied in battery shell, foot step, roof racks and other heat sinks, decorations, bumpers, frames.

Car industry has a rapid change in China. In recent years, market size has expanded and output has continuous increased. The demand for extrusion aluminium profiles has also increased.

Light-weighting, recycling are important topics for domestic and foreign car industry.The innovation of cleaning energy cars is an effective method of relieving of energy crisis, green house effects and emission of pollutants. By now, BEV is a car industry revolution direction. As the usage of BEV in family, business, bus, taxi, transport and other fields popularizing, aluminium consumption in BEV is more than normal vehicles. Components such as main body, wheels, chassis, bumpers, battery chairs are made of aluminium in BEV.

Xingfa Aluminium, established in 1984, is the leading aluminium profile supplier in China. Xingfa Aluminium has five factories in China, which is located in Foshan City Sanshui District, Foshan City Nanhai District, Jiangxi Province Yichun City, Henan Province Qinyang City, Sichuan Province Chengdu City.Xingfa Aluminium has been persisting on the approaches of combining independent research&development and cooperation with domestic and overseas scientific research institutes. Relying on our own four national and five provincial R&D platforms, Xingfa always keeps close cooperation of industry, university and research to provide strong guarantee for the improvement of the company’s technology research and development capability, thus forming self-owned core competence.