In recent years, aluminum extrusions have become increasingly popular among consumers. The popularity is because of the competitive cost of aluminum extrusions and their durability and ease of customization. These qualities have made aluminum extrusions the preferred choice for everyday products, from automobiles to infrastructure.

Architects often use anodized aluminum extrusions to optimize these benefits in their designs. Anodized aluminum extrusions, in particular, can be used for various purposes and have several advantages over other types of aluminium materials. But the real question is, what is anodized aluminium extrusion, and how can it benefit you? This blog will tell you everything about anodized aluminium extrusion and which company will serve you well. So, let’s get started.

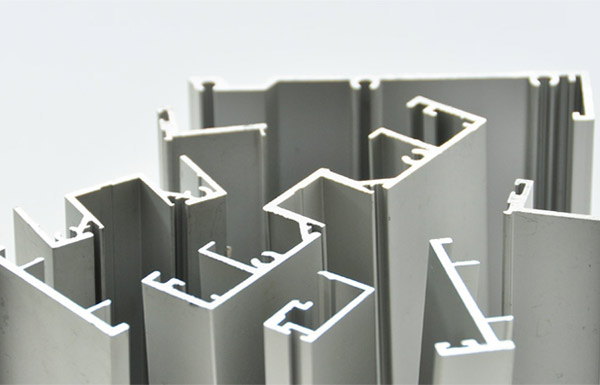

What Are Anodized Aluminum Extrusions?

Anodized aluminum extrusions are a type of structural material that has been treated with an acidic solution or dye to change its color and enhance its durability. The anodizing process causes the aluminium to oxidize and creates a barrier layer to make it more corrosion resistant. The anodized layer is less than 100 microns thick, which means that it is not only incredibly lightweight but also very rigid and sturdy. It has a scratch resistance comparable to that of quartz. The coating has been used since the 1960s for its durability, and now they work as an aesthetic, functional, and decorative element.

The Wide Applications of Anodized Aluminum Extrusions

The application of anodized aluminum extrusions is vast and varied. They are increasingly used in vehicles, architecture, and many other fields. For example, contractors use this as structural support for vehicle body panels to hold the engine and suspension parts together.

Anodized aluminum extrusions can also be used in outdoor structures like streetlamps and lights on walkways. They can be used to make functional parts like handrails and decorative elements like window frames and mailboxes.

The Benefits of Process of Anodizing

The technological advancements in anodizing processes have boosted its use in consumer electronics applications such as mobile accessories and home appliances, further propelling its growth. So let’s look at the benefits of anodizing the material.

1. Improve Corrosion Resistance

Corrosion resistance is dependent on the thickness of the anodized coating. In the anodizing process, the aluminium is treated with a chemical electrolyte bath which increases the thickness of the metal and acts as a barrier to corrosion. The greater the thickness, the longer it takes for corrosion to begin.

2. Improve Wear Resistance

Anodized coatings increase the hardness of the metal’s surface layer, prevent scratching, and resist abrasion. The increased hardness and density also prevent breakage from impact damage during use.

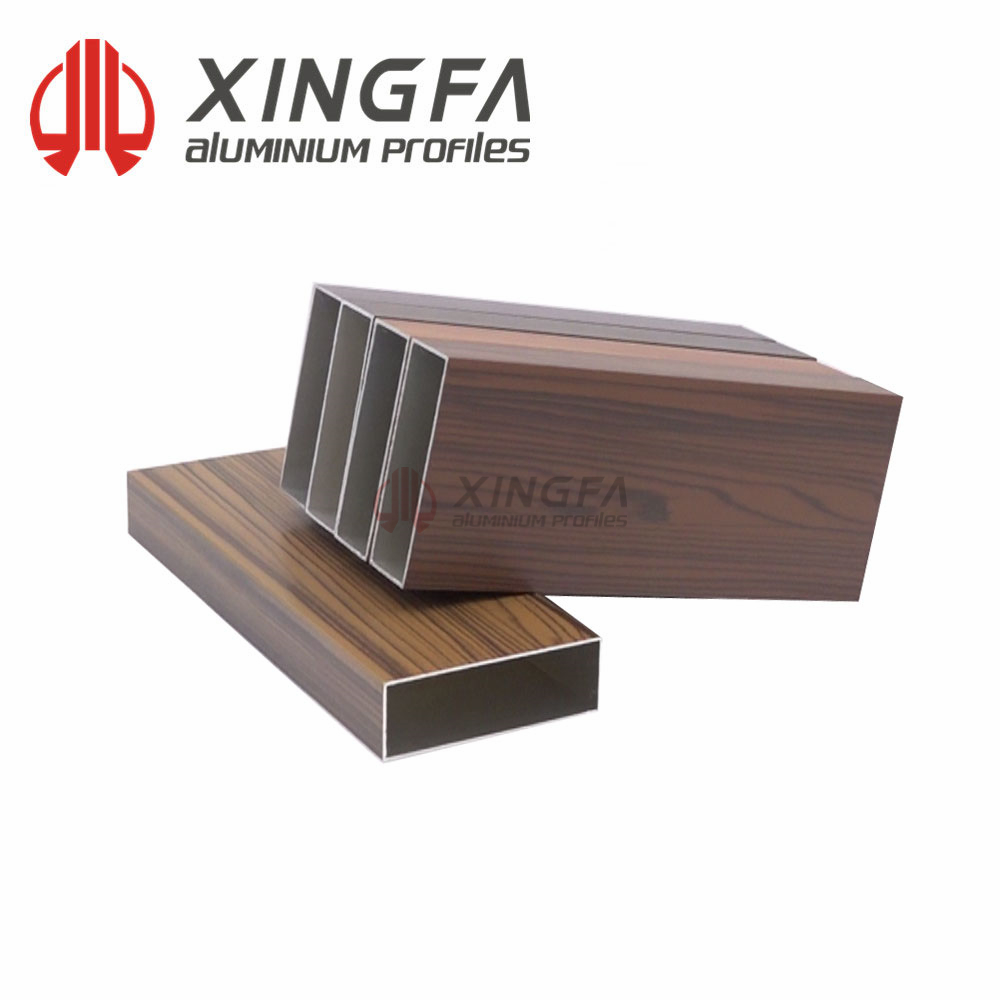

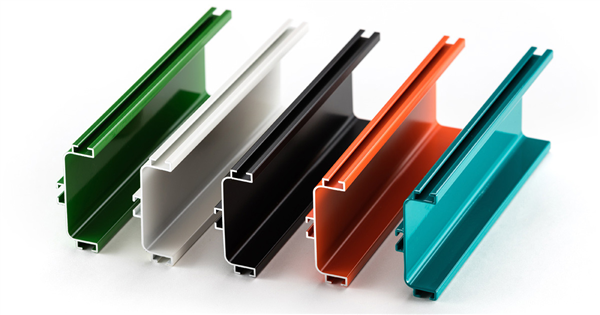

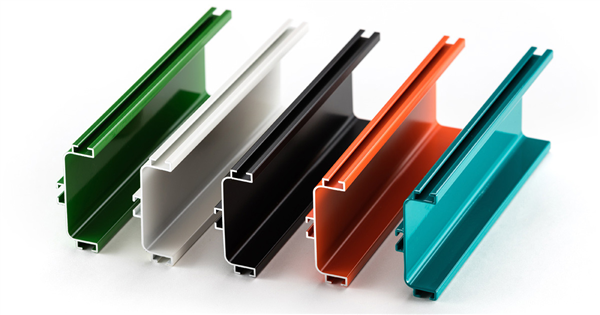

3. Surface Coloring

Because of its non-metallic properties, the anodized coating can be applied over nearly any base metal or alloy without affecting the conductivity or other properties of the part. The process further creates a porous surface layer dyed in different colors and will not fade or change color as the year passes.

4. Improve Insulation

Anodizing process involves submerging the aluminium in a solution containing sulfuric acid. This process creates a protective oxide layer on the surface to improve the product’s insulation and make it much more energy-efficient.

5. Primer for Spray Paint

Spray paint tends to flake off and deteriorate with extreme weather conditions. Anodizing process acts as a barrier and adds a layer on the metal that further increases its adhesion and eliminates the need for priming the surface before painting.

Why Choose Xingfa Anodized Aluminum Extrusions?

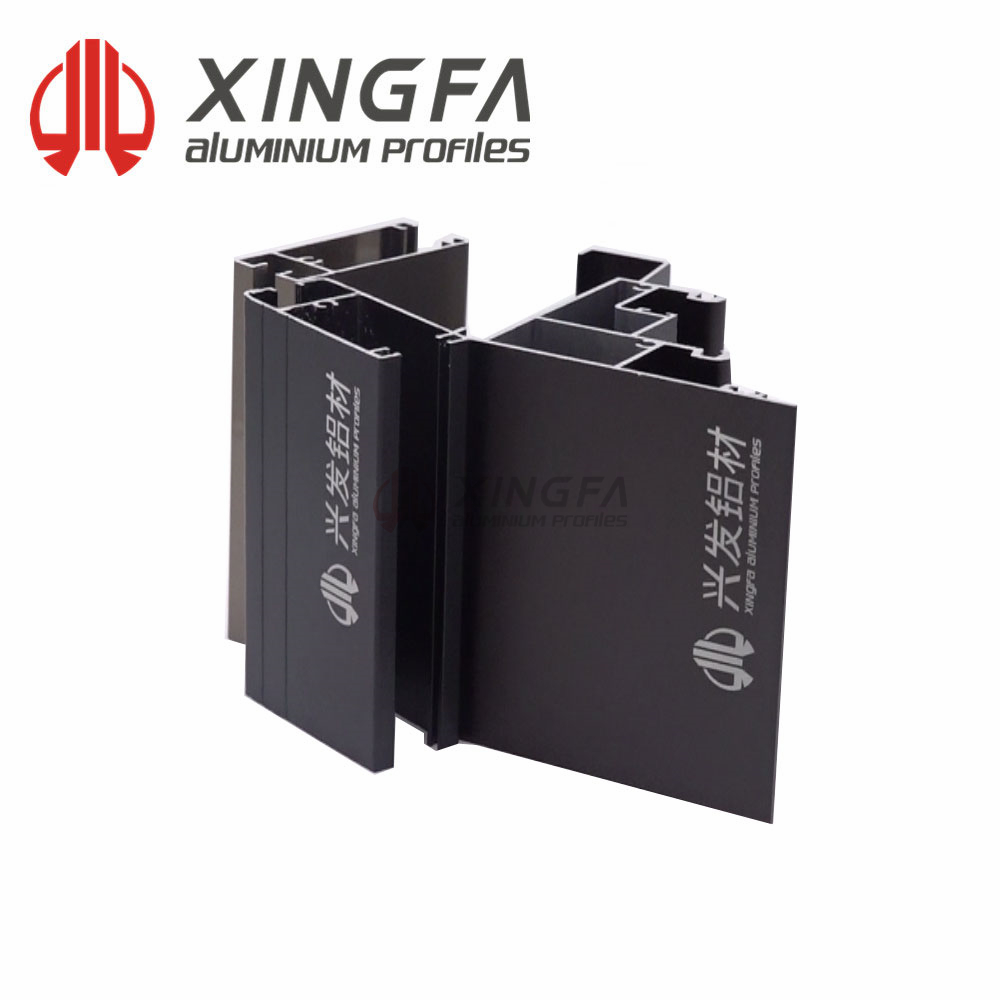

Xingfa is a well-known brand and trusted aluminium profile manufacturer that has been in the market for almost twenty years and is known for developing top-notch aluminium extrusion profiles that last for decades. We offer distinctive extrusion products: one primarily used as a structural material in machine construction, and the other primarily used as a decorative material in residential and commercial environments. The structural line is available in a wide array of sizes, finishes, thicknesses, and styles to suit your needs.

Additionally, we have created a reputation as the top choice for custom anodized aluminium that meets international standards and specifications. So, whether you need aluminium extrusion for decorative design or large-scale application, we can meet your needs with competitive pricing, fast turnaround times, and product availability.

Conclusion

Anodizing can make any aluminium surface corrosion-resistant and give it a uniform color. Anodized aluminum extrusions are used in numerous industries, including aerospace and defense, architecture, entertainment and sporting goods, kitchen cabinets, industrial applications, electronics, telecommunications, and more. So, if you are searching for anodized aluminium extrusion, be sure to contact us for more information on pricing and services.